Lithium battery recycling: accelerating the construction of industrial chain recycling integration

2022-03-25

Lithium battery recycling: accelerating the construction of industrial chain recycling integration

In the context of the rapid increase in the production and sales of new energy vehicles, the installed capacity of power batteries continues to rise. At the same time, as new energy vehicles are gradually scrapped, the scrapped volume of power batteries and energy storage batteries is expected to increase rapidly in the next few years. In addition, driven by the environmental risks of used batteries and the policy dividend period, the power battery recycling industry is expected to meet large-scale volume, superimposing the resource attributes of retired power batteries. It is expected that more and more companies will enter the game, and the implementation of policies will also drive the industry. Standardized development.

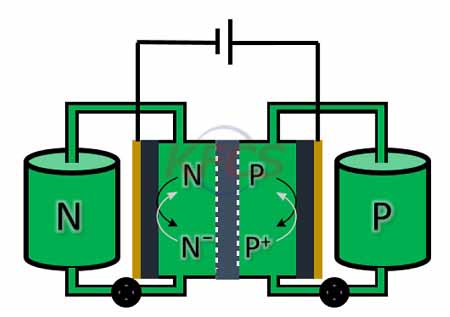

The main purpose of recycling lithium batteries is to extract metals from cathode materials.

Waste batteries are first subjected to pretreatment, including battery classification, discharge, dismantling and pulverization, and subsequent treatment technologies include fire process, wet process and direct regeneration. At present, the wet process is the most widely used. After obtaining metals such as nickel-cobalt-manganese-lithium, they can be processed into metal salts such as nickel-cobalt-manganese sulfate and lithium carbonate. The more types of metals recovered, the higher the recovery rate, and the lower the process cost, indicating that the overall recovery capacity of the battery is stronger.

The recycling channel is the most important link in determining the business model.

According to different battery recycling channels, it can be divided into three types of business models: power battery enterprise recycling mode, industry alliance recycling mode, and third-party recycling enterprise mode. Power battery companies mostly use the power battery company recycling model, extend the industrial chain with their own channel advantages, and open up battery recycling business; vehicle companies and other companies mostly use the industry alliance recycling model to integrate resources in the industry and jointly expand recycling channels; third-party recycling companies lack Channel advantages, it is necessary to independently build a recycling network and give full play to the advantages of the recycling network.

About News

- Volkswagen USA accelerates the layout of power battery recycling

- Lithium battery recycling process and its application

- How to recycle retired batteries

- New energy vehicle battery after scrap recycling method

- Smart Battery Management System (S-BMS)

- Diluted high-concentration electrolyte improves LMB cycling performance, study finds

- Advantages of vanadium batteries

- Lithium battery recycling: accelerating the construction of industrial chain recycling integration

- The history of vanadium battery

- American Vanadium commits to supply CellCube with 3 million liters of vanadium electrolyte per year over the next five years

Products